Features

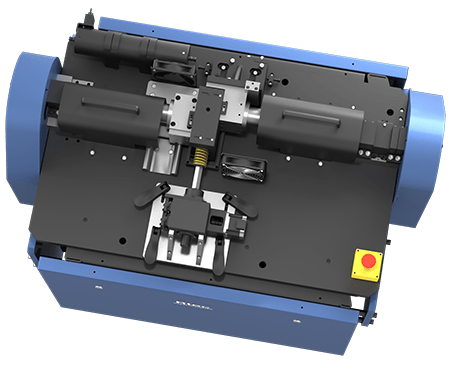

Rtec Instruments’ two roller tribometer has several key design features that makes it the only commercially available tester to run a wide set of conditions and in-line inspection on the same platform. With high data acquisition of 200 Khz, the TwinRoller-3000 obtains high precision measurements.

|

Closed-loop Patented Force Sensor

Capacitive and strain gauge force transducers work across a wide range with no drifts. Real-time servo closed-loop force control. This allows the creation of automatic torque vs load and speed curves.

Precise Temperature Control

Closed-loop temperature controller. From -35 to 150°C

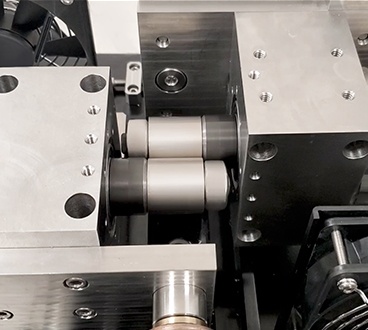

In-line Torque Measurement

Self aligned in-line high resolution torque sensors to quantify surface dynamics in real-time.

|

Accurate Determination of Failures

The twin roller tribometer can accommodate various in-line monitoring sensors to quantify real-time surface dynamics. (acoustic, electrical, etc.)

Rotary Motion

High power, high speed, real-time speed control allows for repeatable data generation.

Integrated In-line Imaging

Image surface with nm resolution without taking sample out of the chamber. Integrated 3D profilometer to look at surface change during the test.

|

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM