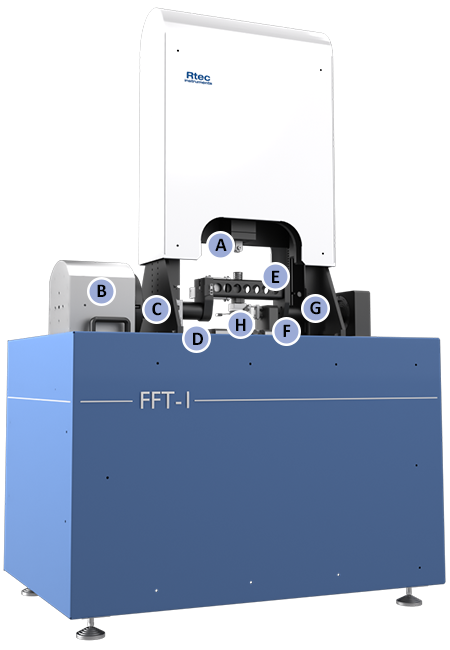

SRV Tester Overview

Main Features:

- 10 µm – 2.8 mm stroke / 0.1 mm to 5 mm stroke

- Up to 300/500 Hz oscillating frequency

- High-resolution piezo sensors

- Electromagnetic coils

- Room to 350°C (optional -40°C, 800°C) temperature

- 3000 N downforce

Rtec SRV test system measures friction and wear of lubricant, oil, grease, and additives in linear oscillatory motion. Generate data compliant with several ASTM, DIN, and ISO standards. Test collected samples from the field or for research purposes.

The SRV tester comes fully automated and computer controlled. The setup is easy to calibrate and comes with standard oil and samples. Additionally, it runs several standard test methods and allows for new custom methods. This insures for future petroleum product standards.

SRV Test Machines Like No Other

This test method covers studying tribology between two contacting surfaces subjected to high-frequency linear oscillation.

|

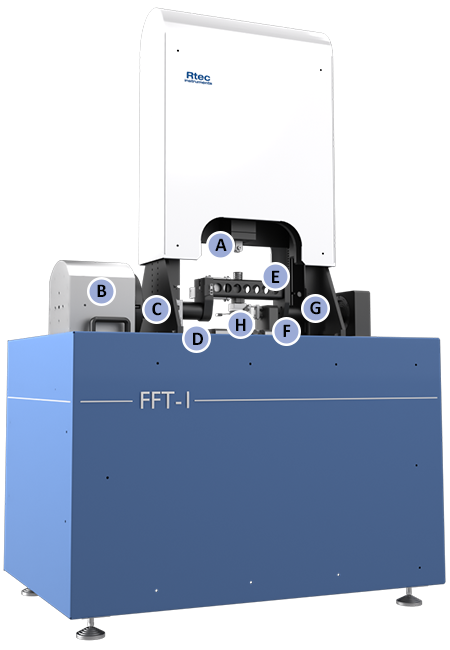

Downforce Control

Real-time downforce control

|

|

Flexure Design -Unmatched Waveform Control

Magnetic flexure design prevents friction of rolling or bearing. In addition, the coil controls the stroke by monitoring smallest of increments of waveform change.

|

|

Voice Coil

Electromagnetic actuator to impart linear reciprocating motion. Dependent on the test-optional additional coils. These are available to double the friction force range.

|

Piezo Friction Measurement

FFT testers come with piezo sensors to measure real-time friction at high frequency. Ultra low noise amplifiers allows detection of minute changes in friction.

|

|

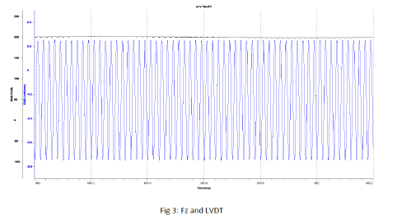

High Accuracy Position Control

The most accurate and precise displacement control in the market. Up to 1nm resolution and micron level of accuracy.

|

Additional In-line Sensors

Acoustic emission for detecting the onset of cracks. ECR measures surface resistance changes to gain more insight on the film thickness.

|

|

Environmental Chambers

The wide temperature range standard room to 180°C (from -40 to 400/800 °C available). Closed-loop temperature control.

|

Liquid Containers, Sample Holder

Customizable liquid and sample holders for standard and non-standard tests.

|

Features

Next Generation

With stroke control from 10 µm, the Rtec Instruments SRV tester simulates many test conditions that are not possible using any other commercially available tester.

|

Traceable Friction Force

Calibrated friction force sensors to NIST traceable standards. This ensures correct absolute friction values.

Platform Rigidity

Vibration dampening frame, symmetrical design, and rigid samples holders yield a high system stiffness. This high rigidity facilitates the high repeatability of data and wear marks with ease.

|

Reliability On Long Runs

The unique flexure suspension guides the magnet assembly without contact or lubrication. Furthermore, the design eliminates performance degradation over time. Instead, It delivers near maintenance free operation.

Stroke control

Ultra precise stroke control allows simulation of many applications. Including studying oil starvation areas and fretting regimes.

|

Choose Your Model

Choice Depends On Multi Function vs. Single Function

|

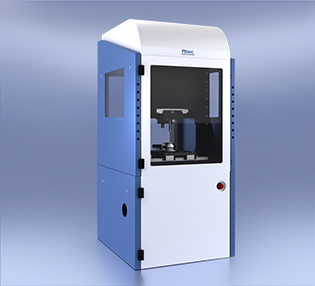

Single Function Tribometer SRV Tester

Dedicated SRV tester for reciprocating friction and wear analysis

|

SRV Test on Multi Function Tribometer MFT-5000

SRV test on the MFT-5000 allows several other friction, tribology, wear tests on the same platform.

|

Data and Analysis

Custom and ASTM Standard Tests Available

|

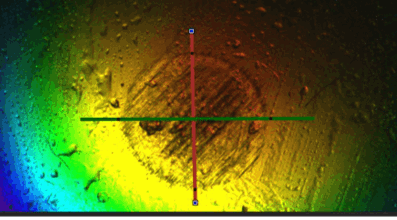

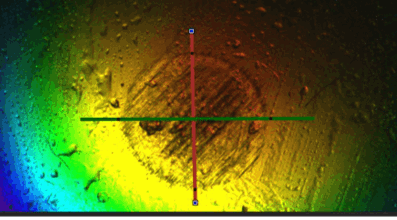

Ball Wear Mark and Volume Wear

3D wear mark of ball surface after the test.

|

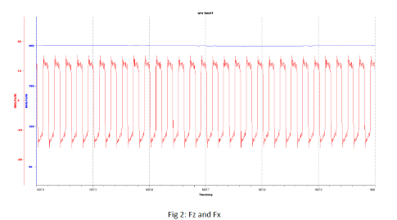

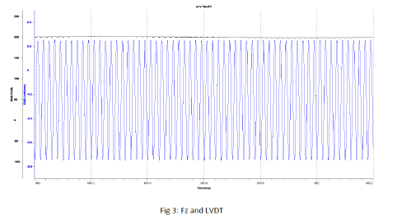

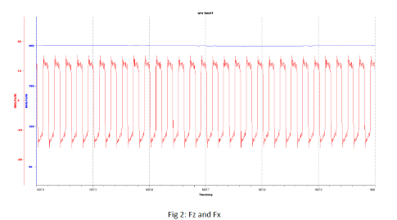

Real Time Friction and Downforce

Real-time friction and downforce data

|

Real Time Stroke Control

Real-time downforce and stroke control.

|

Table 1: COF values at different time intervals

| Test |

COF_15 min |

COF_30 min |

COF_90 min |

| Test 1 |

0.061 |

0.0588 |

0.0589 |

| Test 2 |

0.060 |

0.059 |

0.061 |

Table 2: Wear Scar Diameter (mm)

| Specimen |

Test 1 |

Test 2 |

| Ball Horizontal |

0.4780 mm |

0.4233 mm |

| Ball Vertical |

0.4978 mm |

0.4083 mm |

| Disk Horizontal |

1.348 mm |

1.336 mm |

| Disk Vertical |

0.4273 mm |

0.4380 mm |

Several Applicable Standards

ASTM D5706

Standard Test Method for determining extreme pressure properties of lubricating greases using a high-frequency, linear-oscillation test machine

ASTM D5707

Standard Test Method for measuring friction and wear properties of lubricating grease using a high-frequency, linear-oscillation test machine

ASTM D6425

Equivalent to DIN 51834 part 2, Standard test method for measuring the friction and wear properties of EP lubricating oils using the SRV test machine

ASTM D7217

Standard Test Method for Determining Extreme Pressure Properties of Solid Bonded Films Using a High Frequency Linear Oscillation SRV Test Machine

ASTM D7420

Standard Test Method for Determining Tribomechanical Properties of Grease Lubricated Plastic Socket Suspension Joints Using a High-Frequency, Linear-Oscillation Test Machine

ASTM D7594

Standard Test Method for Determining Fretting Wear Resistance of Lubricating Greases Under High Hertzian Contact Pressures Using a High-Frequency, Linear-Oscillation Test Machine

DIN 51834-1

Tribological test in the translatory oscillation apparatus Part 1: General working principles

DIN 51834-2

Tribological test in the translatory oscillation apparatus

Part 2: Standard test method for measuring the friction and wear properties of EP lubricating oils

DIN 51834-3

Tribological test in the translatory oscillation apparatus Determination of tribological behavior of materials in co-operation with lubricants

DIN 51834-4

Tribological test in the translatory oscillation apparatus Testing the tribological performance of gear and hydraulic fluids

DIN 62136-1

Textile machinery and accessories – Needle and sinker lubricating oils for weft knitting machines

ASTM D7421

Standard Test Method for Determining Extreme Pressure Properties of Lubricating Oils Using High-Frequency, Linear-Oscillation Test Machine

DIN 51834-5

Standardization project in the automotive sector

DIN 51834-6

Standard Test Method for Measuring Friction and Wear Properties of Lubricating Grease Using a High-Frequency, Linear-Oscillation Test Machine

DIN 51834-7

Standard Test Method for Determining Extreme Pressure Properties of Lubricating Greases Using a High-Frequency, Linear-Oscillation Test Machine

DIN 51834-8

Tribological test in translatory oscillation apparatus of bonded solid films DIN 51834-9 Evaluation of plastic greases with plastic specimens

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM