Vacuum Tribometer Overview

Main Features:

- 10-7 Torr vacuum

- mN to 200 N friction and down force

- Cryogenic cooling from -150°C

- Interchangeable tribology, hardness and scratch modules

- Up to 400°C (1000°C) temperature range

Why Vacuum Tribology? – Advancement in space, semiconductor, aerospace, and thin films have resulted in several studies focused on material and coating properties under vacuum. Friction, wear, and adhesion of surfaces under vacuum are very different compared to ambient conditions. To develop next generation vacuum compatible components, and materials it is necessary to test them under conditions close to real applications.

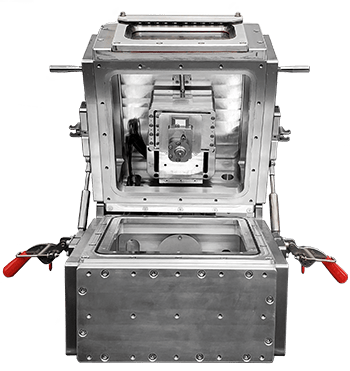

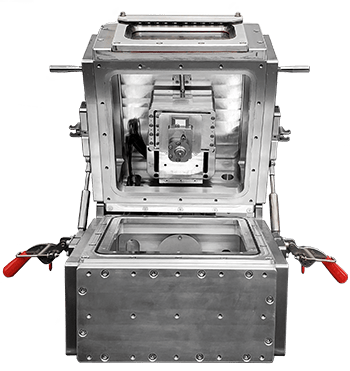

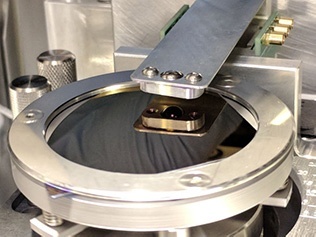

Rtec Vacuum Tribometer MVT-2 comes with a wide force, speed, and test temperature range for analysis of materials properties under vacuum conditions. Unique design with patented force sensors, creates data with high accuracy and repeatability. The open face design provides a complete view of the chamber while changing samples. Run several common friction lubrication and wear tests, such as pin-on-disc, ball-on-disc, and linear reciprocating tests on the same platform. The unique design allows to run indentation, scratch and tribology tests on same platform. The vacuum chamber comes in various standard configurations. Please contact us to discuss your application.

Vacuum Tribometer Features

The vacuum tribometer has several key design features that makes it the only commercial available tribometer to run a wide test conditions on same platform.

|

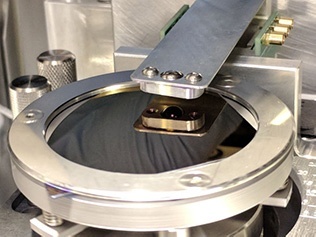

Patented force sensor

- Capacitive sensors work across a high vacuum range with no drifts or degassing.

Cryogenic to high Temperature control

- Close loop temperature controller. Up to -150°C nitrogen cryogenic cooling chamber. Standard 400°C or high power 1000°C heating chamber.

Close loop force control

- Real-time close loop force control during the test. This allows to create automatic friction vs load and speed curves.

|

Quick to reach vacuum

- Reach 10-7 torr vacuum in 45 minutes. Vacuum tribometer has integrated rough and turbo molecular pumps

Rotary and Linear modes

- Rotary speed up to 5000 RPM, Linear speed up to 6 mm/s. Additional Piezo drives for precise motions.

Several Application Modules

- Configeration allows to do scratch, indentation and tribology test on same platform.

|

Environmental Control

The friction coefficient and wear highly depend on environmental conditions. Therefore, tests should occur in conditions close to real application. MVT-2 has advanced close loop controllers to control temperature from -120°C to 400°C on same setup. Temperature can be changed automatically during the test.

|

High Heat and Cryogenic

Cryogenic to high close loop chambers. -150°C to 400°C (1000°C)

|

Environmental Control

Vacuum or inert gas atmosphere for various applications

|

Unmatched Load Cell Technology

Capacitive

The vacuum tribometer MVT-2 comes with patented multi dimension capacitive force sensor. The unique sensing technology provides unparalleled stability and resolution. The wide load range extends from mN to 200 N.

|

Highest Resolution

High resolution to detect minor difference in test

|

High Stability

Negligible drifts over long runs and across wide test conditions

|

High Reliablity

Caliberated to Traceable standards

|

Wide Test Range

Rtec vacuum tribometer comes in several application specific configurations.

|

2D Materials Test

Rotary configuration to look at friction values of 2D materials, thin coatings etc.. Nano Vacuum tribology.

|

Vacuum Grease Test

Rotary configuration to look at friction values of bulk materials or lubricated surface. Micro, Macro Vacuum tribology.

|

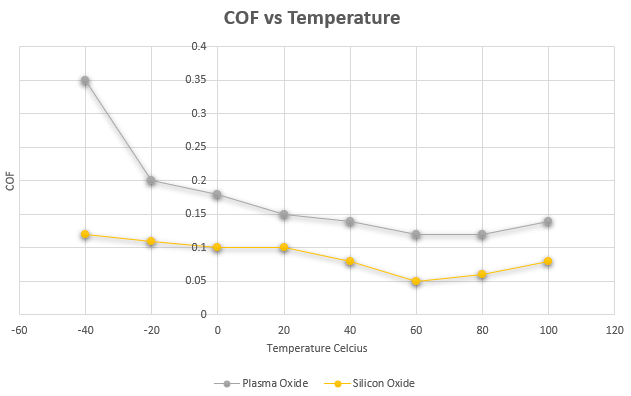

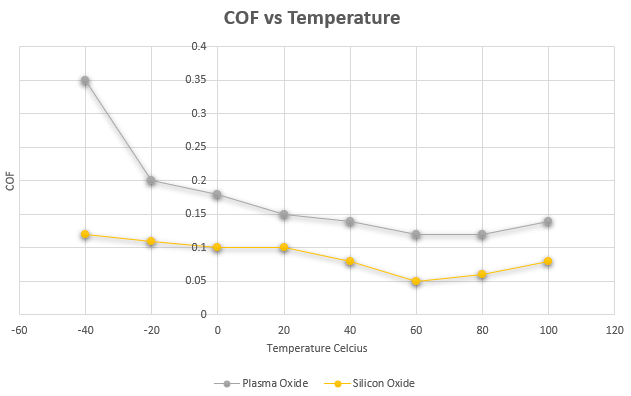

Vacuum Tribology Test Data

|

Data shows coefficient of friction results from vacuum tribometer. The surface treatments were done on two samples.

Sample 1 – the plasma oxide treatment.

Sample 2 – silicon oxide treatment.

- 10 N force

- Velocity 4 mm/s

- Acceleration at 0.1 mm/s2.

- 10-6 Torr

|

Vacuum Tribology Solution

The vacuum tribometer is used extensively across a wide range of industries and applications:

|

-

Space

-

Aerospace

-

Semiconductor

-

Quantum Computing

|

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM