CMP Tester Features

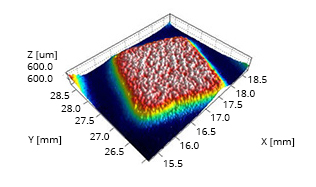

Unmatched Load Cell Technology and Speed

During the polishing process, high resolution in-line force measurements quantify interfacial interactions. To optimize the process, the CP-5000 provides full control of down force. This includes speed and flow rates based on customized test protocols.

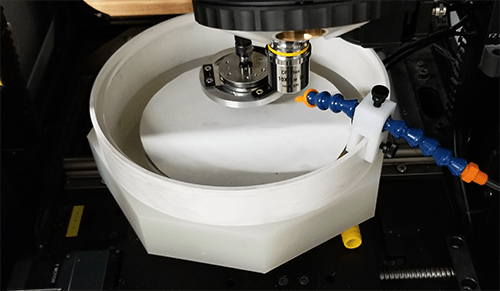

Pad Conditioner

Self-leveling upper pad conditioner holder with both active rotation and horizontal oscillations.

Accommodates conditioner from 0.5 “to 4.25”

|

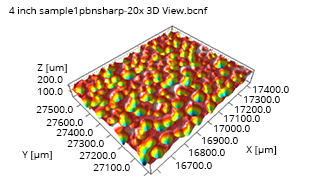

Reliable and Accurate

Each CMP Tester is versatile with many sensors and temperature options. The motorized XY stage comes with fast exchange, providing meaningful data with ease.

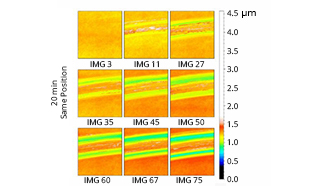

Ease Of Use

The CP-5000 comes with Fast Exchange carriers. As a result, quick and easy mounting of wafer and pads is achieved. The software comes with predefined standard test recipes. The user keeps the ability to easily create new custom recipes.

|

In-line Sensors

Torque – High resolution in-line torque sensors provide high accuracy end pointing.

Acoustic – Acoustic signal that allows qualitative end point. As well as, aids in debris and defects detection during the polishing process.

Temperature – In-line temperature monitoring of pad and area close to wafer polishing surface. This aids in the study of the removal mechanisms.

|

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM