The Lab High Pressure Homogenizer introduced by SCIENTZ Bio is a miniaturized bench-top biological sample processing unit. The instrument has a built-in cooling circulation system to directly cool the homogenizing head and optional homogenizing valves for different applications. It is characterized by high pressure, small size, easy operation, high processing efficiency and large sample output. It is the standard equipment for R&D and production in bioengineering and biopharmaceutical industries.

▌Features

- Invention patent: built-in cooler structure design

- High crushing efficiency: the particle size of the material can be uniformly refined to less than 100nm, the crushing rate is more than 95%.

- High sanitary level: 316L stainless steel material in line with food and drug requirements.

- Versatile options: diamond crushing valve or Staley emulsification valve

- Adjustable pressure: Designed homogenizing pressure is adjustable from 0 to 150MPa.

- Controllable temperature: the inlet and outlet of the cooling connector are connected with the constant temperature tank, which can effectively control the temperature rise of homogenized materials.

- Adjustable flow rate: frequency conversion flow control system, the flow rate can be adjusted according to the need.

- Online exhaust: after exhausting, the adjusted pressure is automatically restored, easy to operate.

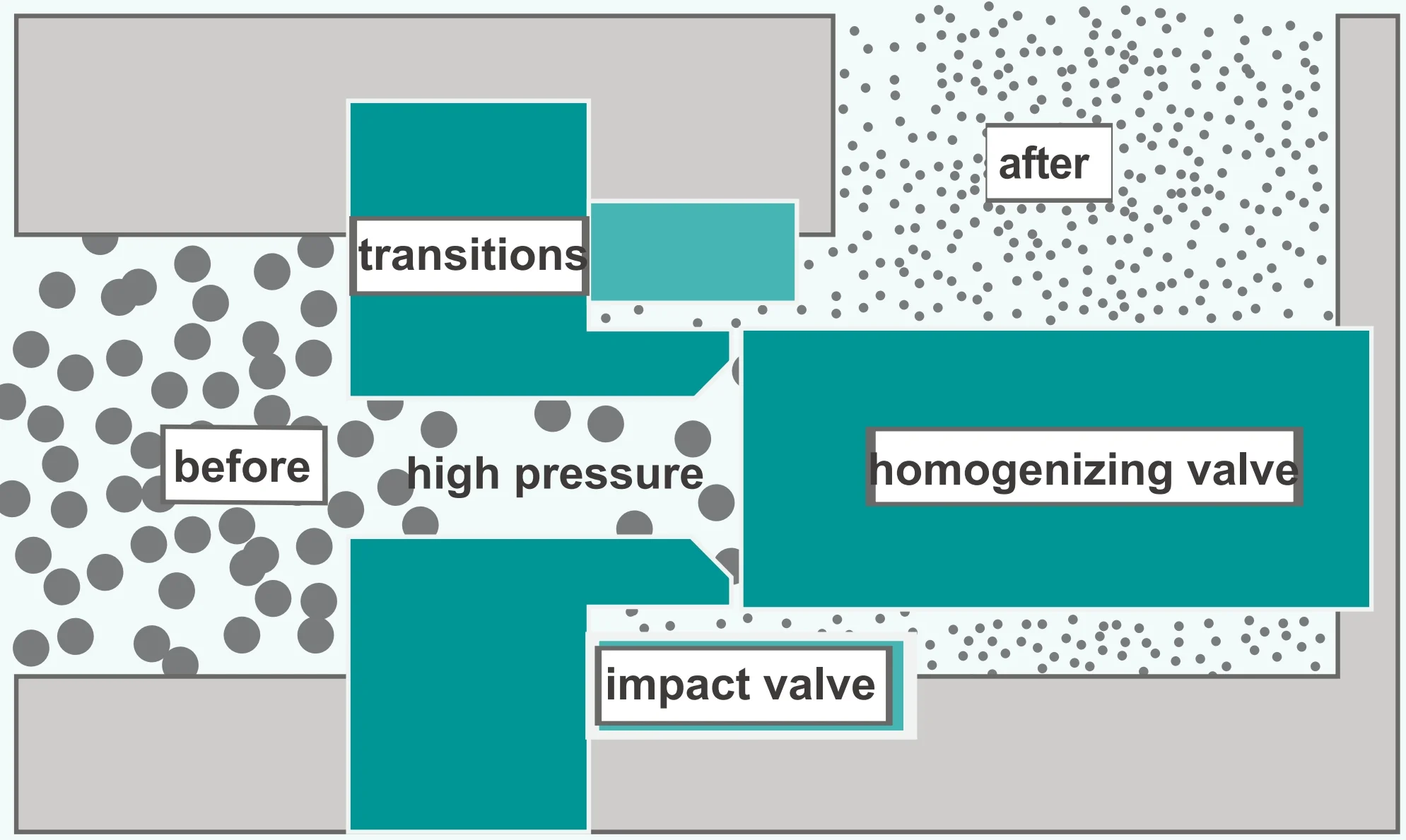

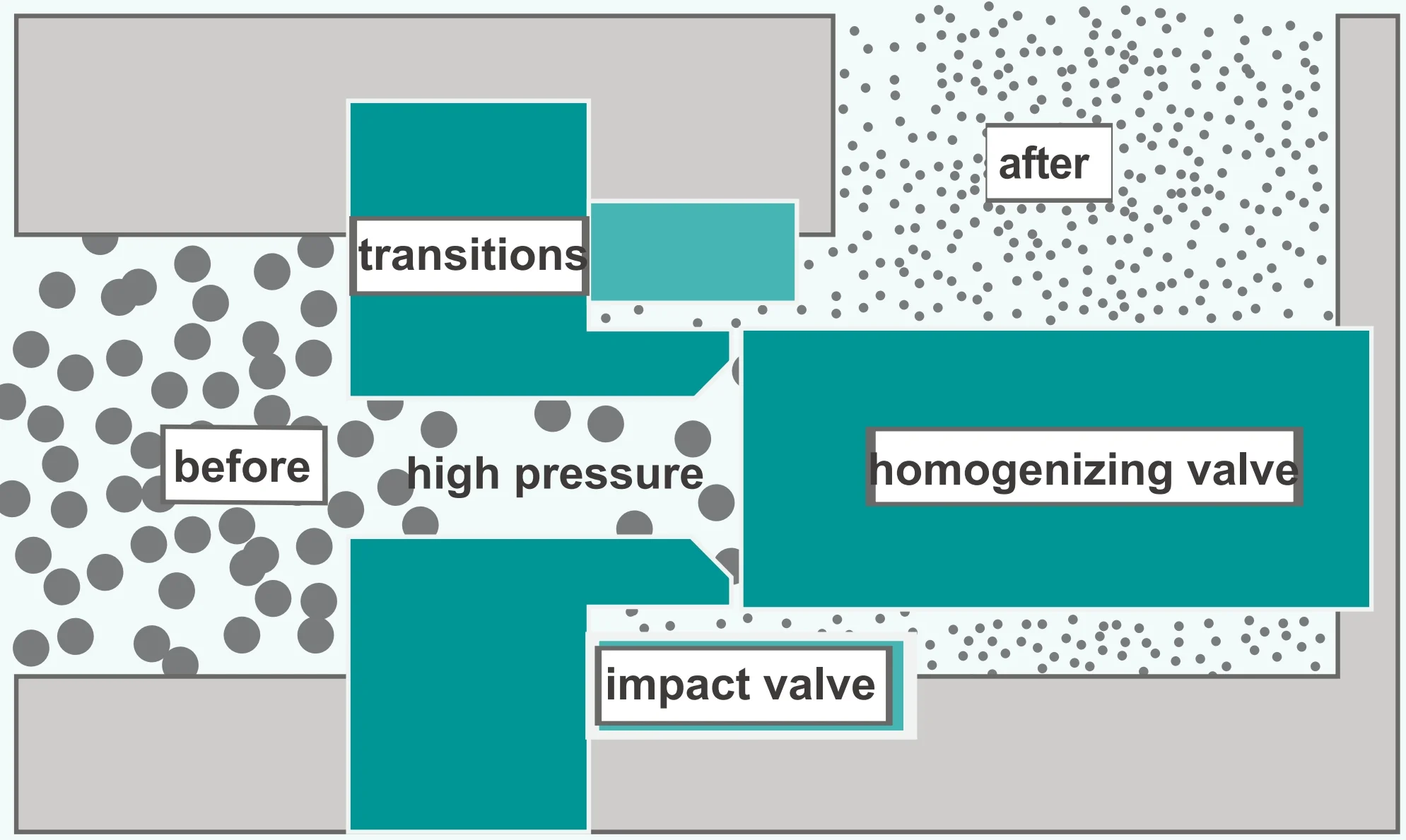

▌Working Principle

The material is transferred from the material cup through a one-way valve into a high-pressure chamber. Pressure is applied by the plunger to adjust and control the sample to the desired high pressure. Instantaneous release through a specific-width throttling gap forms microjets that impact and strike against the valve of an impactor or homogenizer. Sequentially, through the actions of cavitation, impact, and shear, it achieves the purposes of emulsifying dispersion of materials and cell pulverization.

▌Application Areas

Shock Valve (R)

Typically used for crushing of samples, e.g., E. coli, yeast, algae, etc;

Ball valves (PS)

Typically used in the preparation of emulsions, e.g.: wax emulsions, vitamin emulsions, intravenous emulsions.

Food and Beverage: flavors, fruit and vegetable juices, vegetable protein drinks.

Dairy products: milk, ice cream, cream, flavored or fortified milk, yogurt.

▌Main Technical Parameters

|

Model

|

SCIENTZ-150(150PS)

|

SCIENTZ-150A(150APS)

|

| Power Supply |

220V/50Hz

|

three-phase four-wire 380V/50Hz

|

|

Flow

|

6-12 L / hour

|

12-25 L / hour

|

|

Suction Times\Minutes

|

approx 140 times

|

approx 140 times

|

|

Max. Working Pressure

|

1500bar

|

1500bar

|

|

Max. Product Viscosity

|

2000cP

|

2000cP

|

|

Motor Power

|

1.5KW Level 8

|

3.0KW Level 8

|

|

Dimension

|

L800*W460*H450mm

|

L840*W620*H540mm

|

|

Max. Product Temp

|

90℃

|

90℃

|

|

Max. Steam Temp

|

121℃

|

121℃

|

|

Max Feed Particles

|

<500 micron

|

<500 micron

|

▌Partial sample case

Plant proteins: soy protein, peanut protein, sweet potato protein, etc.

Plant tissues: psyllium spores, hawthorn leaves, loquat leaves, ginger plant rhizomes, etc.

Algae cells: Spirulina cells, Candida cells, Chlorella cells, etc. Microorganisms: yeast, E. coli, Schizosaccharomyces cerevisiae, etc.

Liquid food: food and beverage, dairy products, jelly, etc.

Paint color paste: carbon black paint color paste, phthalocyanine green paint color paste, phthalocyanine blue paint color paste, purple 23 paint color paste, etc. c

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM